ORBIS CORPORATION

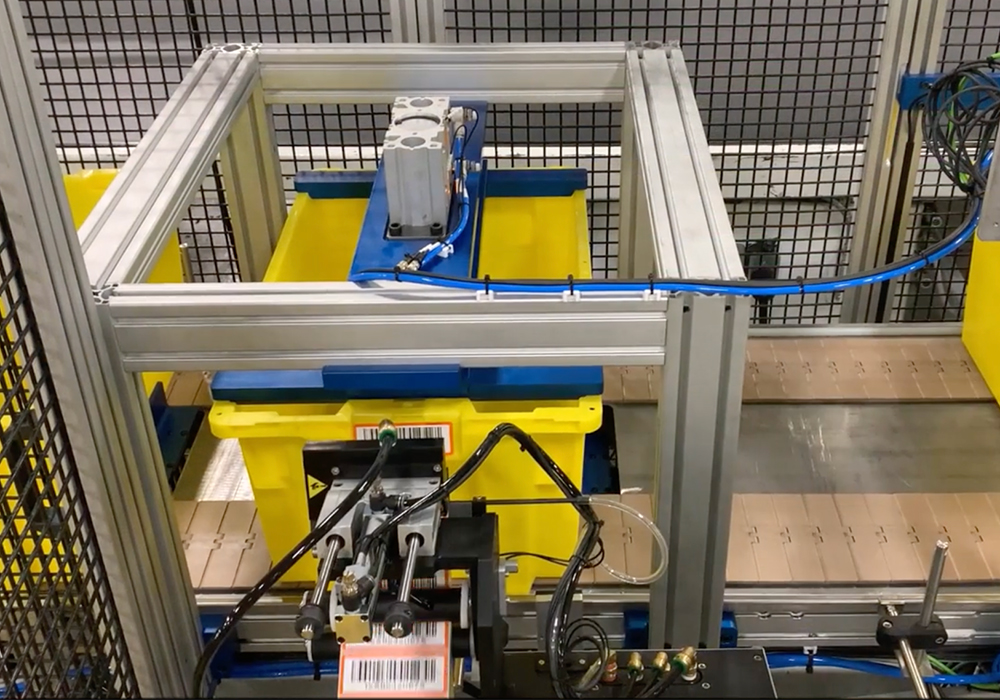

ORBIS is helping major U.S. grocers meet the dramatic increase in online shopping and curbside delivery. Retailers use ORBIS totes to fulfill online orders that are picked up curbside by consumers. ORBIS’ Pally, a hybrid dolly/pallet with wheels, is also used to wheel orders from store to curb.

Master recyclers.

Master recyclers. We report our emissions to the Carbon Disclosure Project (CDP), an independent nonprofit holding the world’s largest database of primary corporate climate change information.

We report our emissions to the Carbon Disclosure Project (CDP), an independent nonprofit holding the world’s largest database of primary corporate climate change information.